Portfolio

Our services

Custom sheet metal manufacturing

Switchboards - comprehensive solutions

Punching

Punching of holes of various shapes, thread cutting, pressing, embossing, perforations, centering points, countersinking, customer logo marking, necking, recess forming

Technologies—3x Trumpf TruPunch 5000 (2x with SheetMaster robotized system and 1x with ToolMaster system). Max. sheet metal thickness: 2.5 mm. Max. sheet format: 1,250 x 2,500 mm

(medium format).

Combined technology of punching and laser cutting—Trumpf TruMatic 6000.

Welding

Flame welding, arc welding, MIG/MAG and TIG, welding of steel, aluminium and stainless steel, point welding

Technologies—manual welding, MIG/MAG welding robot, JESVA and TECNA point welding machines.

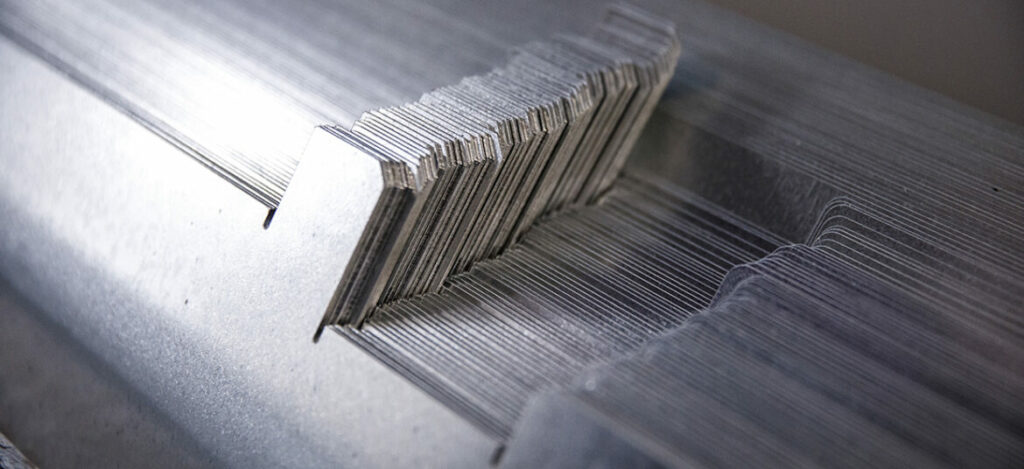

Laser welding

High-quality and perfect welds technically and aesthetically (no side burns)

Welding without additional material, continuous welds without the need for final grinding or cleaning, excellent results even for welding thin sheets.

Bending

Manual or automatic bending

Technology – 8x TruBend (7036, 5050, V85, 2x V130, 5130 and 2x 5170 with BendMaster. Pressing force: 36 – 170 tons. Max. bending length: 4200 mm.

Laser cutting

Cutting with laser beam, engraving

Equipment – 1 Trumpf TruMatic 3030 machine, 1 Trumpf TruLaser 5030 Fiber machine. Max. sheet thickness: black: 20 mm, stainless steel: 12 mm, aluminum: 8 mm, copper and brass: 6 mm. Max. sheet size: 1500 x 3000 mm (large format).

Sheet metal forming

Forming in special machines

Technologies—2x eccentric press LEXN 100C and LEK 250 (shaping force 100 t and 250 t).

Fine Machining Operations

Manual/machine deburring, countersinking, threading, drilling, manual/machine grinding, cutting, manual/machine straightening

Technologies—stand drilling machines, threaders, manual/machine grinders, machine saw, bending machine.

Pressing

Pressing/cartridge fixing of fasteners, riveting, clinching

Technologies—PEM Serter, Haeger, Brecker and TOX machine presses.

Simple assembly operations

Manual parts cleaning, parts packaging

Surface Finishing

Powder coating, cataphoresic coating, galvanizing, nickeling, etc.

Printing

Screen printing and pad printing.

Core Services

We are here to provide you with the key services you need. We offer the production of sheet metal parts, sub-assemblies and assemblies as well as complete products including logistics support. When it comes to switchboards, we can supply not only enclosures and passive elements, but also complete turnkey solutions. With state-of-the-art machinery, programs and superior technology, we achieve the best results for our demanding customers.

Local production, global quality.

Our production is centralized in the Czech Republic and is carefully supervised by top experts with many years of experience. Thanks to them, we can guarantee the highest quality of our products and services.

Individual approach, excellent results

We understand that each client has their own requirements and goals. That is why we emphasize an individual approach to each project. Our solutions are always tailored to meet business plans and production specifications.

If you are seeking a partner for a comprehensive custom manufacturing solution, contact us and let us help you achieve your business goals.

Our clients

Industrial refrigeration

Transport equipment

Telecommunications

Industrial automation

Electro LV and HV

Do you have any questions?